K

Features

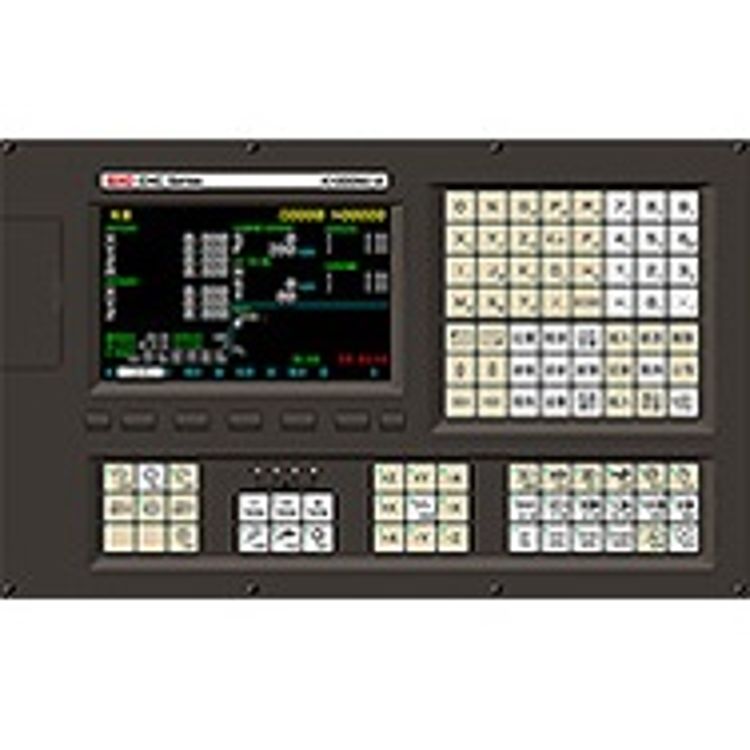

Equipped with a 7 inches TFT color LCD with the resolution of 800×480.

Be able to process up to 1000 blocks of program per second, which makes the high-speed & mini-line cutting available.

Input and output signals’ points can be extended up to 512/512 by CAN bus.

The rapid traverse rate reaches up to 60 m/min and the feed rate reaches up to 30 m/min.

Support tools regulation instrument and provide a wealth of tool regulation functions such as the rectangle center tool regulation function, the circle center tool regulation function etc.

Equipped with U-disk port through which CNC systems provide the following functions: store and recover systems’ software and machining data, perform DNC machining by executing a program in U-disks.

Provide a wealth of software control functions such as the macro-B function, the additional workpiece coordinate system function, the helical interpolation function and so on.

Provide a wealth of system control functions such as the high-speed & high-precision function, the time-limitation function, the pitch-error and backlash compensation functions, the function of executing multi-blocks of commands in MDI mode, the function of protecting parameters & programs and so on.

Support the function of servo spindles, which makes the spindle orienting function and the rigid tapping function available.

Specification

|

Item |

Specification |

|

|

Model |

K1000Mi-A |

K1000M4i-A |

|

Controlled axis number |

3 (X, Y, Z) |

4 (X, Y, Z,4) |

|

Simultaneously controlled axis number |

3 |

4 |

|

Interpolation |

Linear, arc, helix, polar

coordinate(optional) |

|

|

Least command unit |

0.001mm or 0.0001inch |

|

|

Maximum command |

±99999.999 mm |

|

|

Rapid traverse rate |

60000 mm/min |

|

|

Maximum feed rate |

30000.000 mm/min |

|

|

Override of feed rate |

0~150% |

|

|

Program memory space, program number,

electronic disk number |

640KB/128/3 |

|

|

Screen |

7 inch TFT |

|

|

800×480, Chinese/English menu |

||

|

Additional operator’s interface |

Additional operator’s panel Independent operation box |

|

|

Display |

Position, machining time, workpiece

counter, date, time, speed etc. |

|

|

Graph |

Parameters setting and paths displaying |

|

|

Tool compensation |

Tool length compensation Tool nose radius compensation |

|

|

Type C tool compensation |

||

|

Pitch error compensation Backlash compensation |

Supplied |

|

|

Spindle function |

Gear shifting Analog spindle control Rigid taping control |

|

|

Miscellaneous function |

Spindle CW/CCW/brake control Lubrication control Coolant control Other optional function according to

customer’s application |

|

|

Program editing |

Incremental/absolute/mixed/decimal point

programming |

|

|

Workpiece coordinate system |

G54~G59 |

|

|

Subprogram calling |

Supplied |

|

|

Metric/inch programming |

Supplied |

|

|

Communication function |

RS232 serial port (baud rate reaches up to

115200 bps) |

|

|

Remote control |

Transmit machining programs |

|

|

U-disk |

Supplied |

|

|

Macro programming |

Macro A or Macro B |

|

|

Emergency stop Stroke limitation check |

Support up to 3 emergency stop signals Stored stroke limitation check Hardware stroke limitation check |

|

|

Alarm |

P/S alarm, driver alarm, overtravel alarm,

system error alarm, external alarm etc. |

|

|

Acc./dec. control |

Linear and exponential |

|

|

Reference position returning |

Automatic Manual |

|

|

Electronic gear ratio |

1~65535/1~65535 |

|

|

Machine control |

Machine lock Feed hold Optional block skip |

|

|

Feed control |

Automatic, manual, step, hand wheel |

|

|

I/O point number |

DI:40 DO:24 I/O point number can be extended up to

512/512 using CAN bus |

|

|

Driver |

Digit AC servo driver |

|

|

Tool offset number |

32 |

|

|

Tool rest control |

By PLC process |

|

|

Drilling/taping/boring cycles |

Supplied |

|

|

Plant specifying |

G17/G18/G19 |

|

|

DNC |

RS232 or U-disk |

|

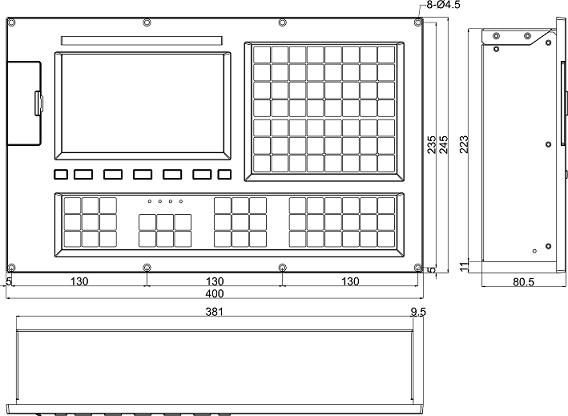

Dimension

Accessories

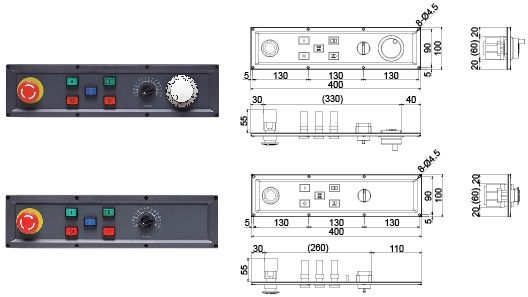

The additional panel:

Remote IO module:

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.