K1000TIV is a new generation superior

turning center CNC system with high performance 32-bit microprocessor and open

PLC process. It is employed with 10.4 inch color LCD display. It can control 4

feeding axes, 4 simultaneously controlled axes. It has horizontal and vertical

installation structure. It can be matched with KND or YASKAWA Digital AC servo

driver. K1000TIV is the best choice for full function CNC turning machine and

Features

Apply 32-bits powerful CPU to achieve high-speed, high-precision control. The maximum speed reaches up to 30 m/min

10.4 inch TFT LCD with the resolution of 640×480.

Six layer main board applying SMT, custom-build FPGA, high integration technology, perfect structure design ensures that the system has high reliability and high anti-interface capability.

Support the open-style PLC function to meet the secondary development of the machine tool builder.

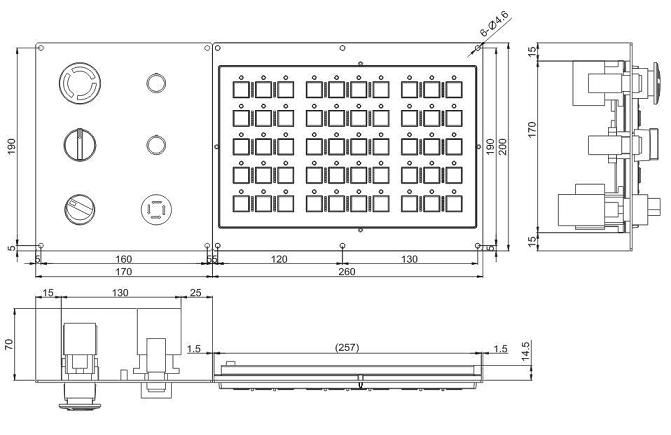

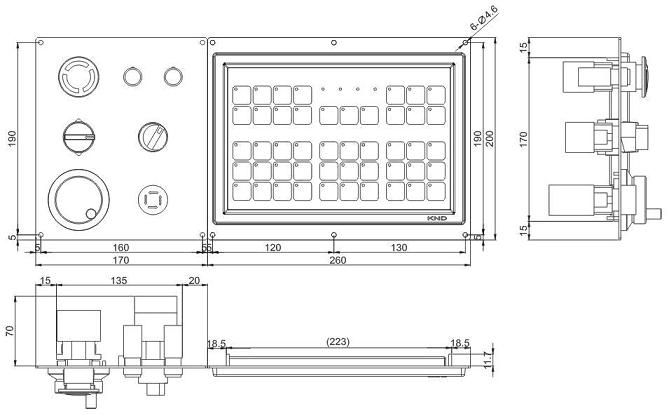

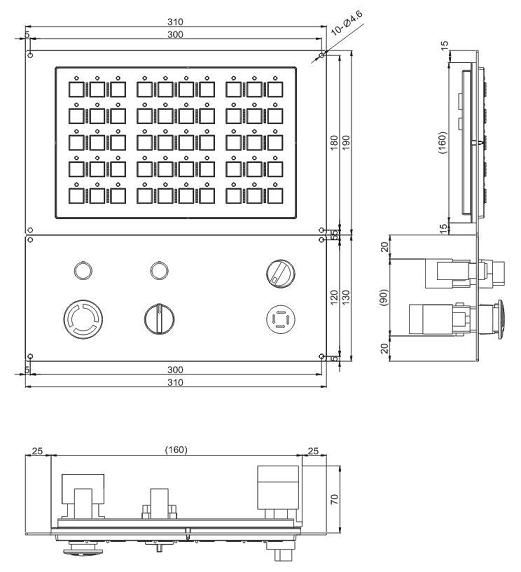

Two types of machine control panels including the standard panel with film-buttons and one with pushed buttons are available. On the later one the functions of the 50 pushed buttons and 50 lamps are able to defined by customs.

Remote I/O modules based on CAN bus can be use to extend the number of I/O points up to 512/512.

Chinese operation interface and full help information make the operation more conveniently.

Perfect self-diagnosis function. Display the internal and external states in real time and alarms will be issued timely when some abnormity happens.

Powerful instruction execution ability to achieve the high-speed, small-line-section machining

High-speed DNC machining are available based on the transmit rate reaches up to 115200 bps and large program buffer space.

640 kB internal program memory space. U-disk port can be use to extend the space of program and to perform DNC machining.

Rich NC functions: macro program B, rigid tapping, local coordinate system, coordinate system rotation, coordinate scaling, polar coordinate system, etc.

Specification

|

Functions |

Specifications |

Functions |

Specifications |

|

Controlled

Axes |

X、Z or X、Y、Z、C |

Metric/inch

conversion |

Provided |

|

Simultaneous

Controlled Axes |

2 or 4 |

Communication

Function |

RS232

port(Baud Rate up to 115200) |

|

Interpolation

Mode |

Linear/Circular |

Program,

parameter, offset data download from / upload to PC available |

|

|

Least

Programming Unit |

0.001

mm or 0.0001 inch |

Remote

Control |

Download/Upload

PLC Program, Machining Program |

|

Largest

programming value |

±99999.999

mm |

USB

Interface |

Yes |

|

Max

Rapid Travel Speed |

30000.000

mm/min |

Macro

Program |

Macro A

or B |

|

Max Feed

Speed |

15000.000

mm/min (or 30000m/min) |

Emergency

Stop, Stroke Limit |

Emergency

stop signal, soft and hard travel limit |

|

Feedrate

Override |

Manual /

Auto 0~150% 16 Levels |

Alarm |

P/S

alarm, driver alarm, over travel alarm |

|

Instant

adjustment by band-switch (on Add-on panel) |

System

error alarm, external alarm |

||

|

Program

Storage /Count / Electronic Disk |

640kB/128/3 (640kB/512/3

optional) |

Acceleration

/ Deceleration |

Linear,

exponential |

|

Monitor |

10.4

inch color TFT LCD |

Return

Reference Point |

Manual

and Auto |

|

Resolution

640×480 / Chinese or English user interface |

Electric

Gear Box Ratio |

1~127 :

1~127 |

|

|

Additional

Operation Interface |

Additional

panel, separated control box |

Machine

Tool Control |

Machine

tool lock, feed hold, program block skip |

|

Display |

Position,

timer, cycle counter, date, time, speed and so on |

Feed

Control |

Auto,

manual, jog, hand wheel |

|

Graphics

Function |

Graphic

parameter setting and graphic display |

DI/DO

Ports |

DI: 40

points, DO: 24 points Expansible

up to 512 / 512 via CAN bus |

|

PLC

Function |

Open PLC |

Driver

Configuration |

Digital

AC Servo Driver |

|

Tool

Compensation |

Tool

length compensation |

Measurement

Function |

Provided |

|

Backlash

Compensation / Pitch Error Compensation |

Cutter

length, tool nose radius compensation (Compensation C) |

Simple/Complex

Cycles |

Provided |

|

Spindle

Function |

Gears

control, analog voltage, rigid tapping |

Thread

Cutting |

Straight

Thread, Taper Thread, End Thread, Variable-pitch Thread |

|

Auxiliary

Functions |

Manual /

MDI / auto controlled spindle forward or backward turning |

Diameter/Radius

Programming |

Provided |

|

Stop,

coolant on / off, lube on / off |

Per-min/Per-Rev

Feed Control |

Provided |

|

|

Program

Edit |

Relative/Absolute/Mixed

Programming, Decimal Programming |

Constant Surface

Speed Control |

Provided |

|

Work

Coordinate System |

G54~G59 |

Tool

Offset |

16 |

|

Subroutine

Call |

Provided |

Tool

Control |

PLC

Programming Control |

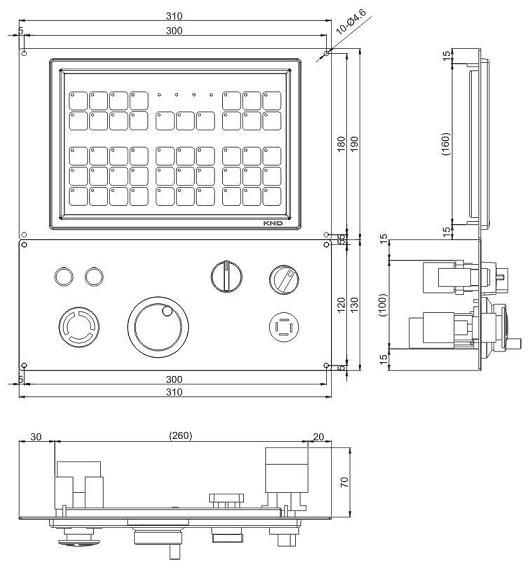

Dimension

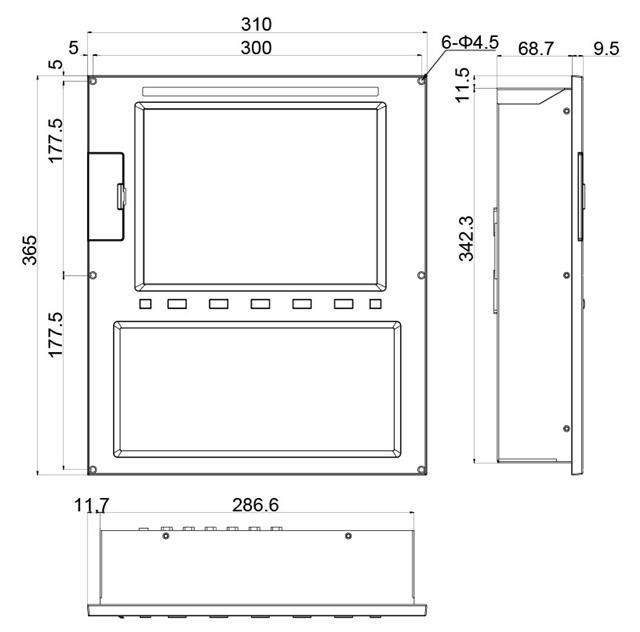

Horizontal Layout (H):

Vertical Layout(V):

Accessories

Horizontal Layout (H)

Machine control panel (pushed button) and additional panel:

Machine control panel (film-button) and additional panel:

Vertical Layout(V)

Machine control panel (pushed button) and additional panel :

Machine control panel (film-button) and additional panel :

Remote IO module:

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.