K100Ti-B is a popular turning machine CNC system with new software and hardware design. It can control 2 feeding axes, 2 simultaneously controlled axes. It can be matched with KND Digital AC servo driver. K100Ti-B is suitable for economy CNC Lathe.

Features

7 inch TFT color LCD with the resolution of 800×480.

The system has both the U-disk and RS232 interface, through which it is possible to exchange information between system and U-disk or computer. The system software can be updated with a U-disk.

The X-axis and Z-axis can be controlled simultaneously and the accuracy can reach up to 1μm.

Various of machining operations are satisfied by 28 G codes and 26 M codes.

The max rapid traverse rate is 24 m/min, and the max feed rate is 20 m/min.

Support tool length compensation, tool nose radius compensation and backlash compensation.

Taper thread, straight thread, and variable-pitch thread with both single-start and multi-start can be cut; The length, angle and speed for thread retreating can be specified.

With the function of linear and exponential acceleration/deceleration control and block pre-processing, high-speed and high-precision machining can be satisfied.

Specification

|

Item |

Description |

Specification |

|

|

Axis |

Controlled

Axis Number |

2 (X,

Z) |

|

|

Simultaneously

Controlled Axis Number |

2 |

||

|

Command |

Lease

command unit |

0.001

mm |

|

|

Least

movement unit |

0.001

mm |

||

|

Maximum

command |

±9999.999

mm |

||

|

Feed |

Rapid

traverse rate |

24000mm/min

(Max.) |

|

|

Feed

rate |

per min |

1~20000mm/min |

|

|

per

revolution |

0.0001~500.0000

mm/r |

||

|

Thread

lead |

0.0001~500.0000

mm |

||

|

Automatic

acc./dec. |

Supplied

(Linear, exponential) |

||

|

Feedrate

override |

0~150% |

||

|

Manual |

Manual continuously feed Manually return to reference point Step

feed |

One axis at the same time ×1,

×10, ×100 |

|

|

Hand

wheel |

Supplied |

||

|

Interpolation |

Positioning Linear interpolation Circular

interpolation |

G00 G01 G02/G03 |

|

|

Debug

function |

Dry running Single

block funning |

Supplied |

|

|

Canned

cycle |

Internal/external

cylindrical turning |

G90 |

|

|

Thread

cutting cycle |

G92 |

||

|

Tapping

cycle |

G93 |

||

|

Facing

cycle |

G94 |

||

|

Multiple

canned cycle |

Finishing

cycle |

G70 |

|

|

Outer

diameter rough turning |

G71 |

||

|

Rough

facing cycle |

G72 |

||

|

Canned

turning cycle |

G73 |

||

|

End

peck drilling cycle |

G74 |

||

|

External/internal

slotting cycle |

G75 |

||

|

Multiple

thread cutting cycle |

G76 |

||

|

Enhanced

thread cutting cycle |

G78 |

||

|

Coordinate

system and dwell |

Dwell

(second) |

G04 |

|

|

Coordinate

system setting |

G50 |

||

|

Auto

coordinate system setting |

Supplied |

||

|

Mode |

MDI,

Auto, JOG, Step, Edit |

Supplied |

|

|

Safety

functions |

Stored

stroke check |

Supplied |

|

|

Mask

stored stroke check |

Supplied |

||

|

Emergency

stop |

Supplied |

||

|

Program

storage and edit |

Memory

space and program number |

32kB,

63 |

|

|

Editing |

Insert,

modify, delete, copy |

||

|

Search

function (Program no. sequence no. address, word) |

Supplied |

||

|

Decimal programming Optional

block skip |

Supplied |

||

|

Electronic

disks |

Supplied,

6 regions |

||

|

Display |

TFT LCD |

800×480,

7 inches |

|

|

Position

information, program, tool offset, alarm, diagnosis data, debug, parameter |

Supplied |

||

|

Graph,

workpiece count |

Supplied |

||

|

M, S, T |

I/O

points: 20/16 |

Input:

4(panel)+16(machine) |

|

|

Miscellaneous

function |

M +

2-digit |

||

|

Spindle

function |

S +

2-digit |

||

|

Analog spindle (s+4digit) Constant

surface speed cutting |

Supplied

(8-digit D/A) |

||

|

Tool

function |

T01~T08 |

||

|

Tool

rest signal checking function |

Supplied |

||

|

Compensation

function |

Memory |

±6, 16

group |

|

|

Input

by counting |

Supplied |

||

|

Input

by measuring |

Supplied |

||

|

Type C

tool compensation function |

Supplied |

||

|

Backlash

compensation |

Supplied |

||

|

Switch |

Program switch Parameter

switch |

Supplied |

|

|

Communication |

RS232 |

Supplied |

|

|

U-disk |

Supplied |

||

|

Other

function |

Circular

radius R setting |

Supplied |

|

|

G10 |

Supplied |

||

|

Electronic

gear ratio |

Supplied |

||

|

Remember

workpiece coordinate |

Supplied |

||

|

Back

too rest function |

Supplied |

||

|

Start

execution at random position |

Supplied |

||

|

Rotary

axis function |

Supplied |

||

|

Clock

and machining time |

Supplied |

||

|

Optional

function |

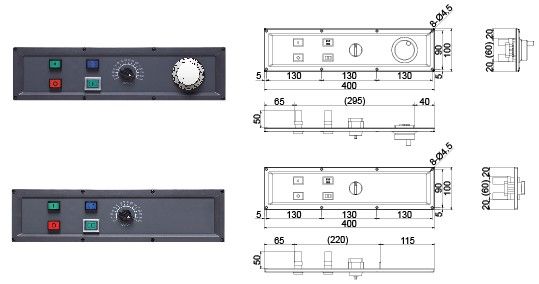

Additional

machine operator’s panel |

Optional |

|

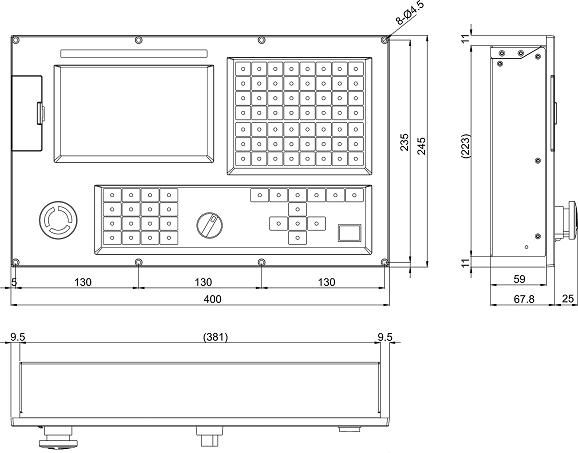

Dimension

Accessories

The additional panel:

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.