Century Star HNC-18i(III) /T system adopts

advanced open architecture, built-in Industrial Personal Computer (IPC),

high-performance 32-bit CPU, 7-inch color LCD display, and standard operation

panel. The system integrates the interfaces for feed spindle, spindle,

hand-held units, and built-in PLC, adopts high-capacity disk storage, and

provides the function for CF and USB program exchange. HNC-18i Ⅲ system is

generally used for the control in CNC turning and milling machines, and simple

machining centers. The system has the following major advantages:

1. Low cost

2. High performance

3. Compact structure

4. Easy -to -use operation

5. High reliability

Features

1. Maximum coordinate axes: 3

2. Compatible with various pulse

instruction AC servo drives and stepper motor drives

3. Configured with standard machine panel,

and I/O interfaces with available PLC

4. Configured with switch-value input (32)

and output (24) interfaces, hand-held unit interface, simulation spindle

control and encoder interfaces

5. Adopting 7-inch LCD (resolution: 800 x

480) and full Chinese operation interface, providing the functions for

identifying faults and reporting alarms, and displaying graphical machining

paths, which enables users to easily operate and use the system

6. Adopting international standard G-code

programming mode and being compatible with popular CAD or CAM automatic

programming systems, and providing functions for linear, circular, and thread

interpolation, fixed loop programming, rotation, image resizing, mirroring,

tool compensation, and customized macro programming

7. Providing function for constant small

line segment machining, which is suitable for part processing of complicated

modules

8. Providing the function for breakpoint

save and machining recovery

9. Providing the functions for backlash

compensation and single or bi-directional pitch error compensation to improve

the machining precision

10. Providing machining capability based on

large amount of NC programs (a maximum of 2 GB G-code programs)

11. Providing embedded RS232 communication

interface to achieve data communication between computers and CNC machines

12. Providing 512 KB storage capacity, in

which 400 KB can be reserved for user’s part programs and the 112 KB can be

reserved for user data

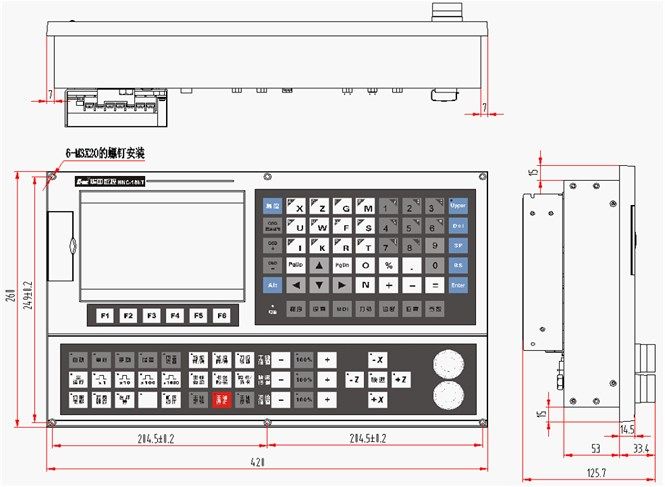

13. The dimension and size of the system is: 420 x 260 x 126 (W x H x D, unit: mm)

Specifications

|

CNC function |

Maximum controllable axes: three feed axes and one spindle Maximum coordinate axes: three axes |

|

Minimum resolution: 1μm |

|

|

Automatic control of acceleration and deceleration (straight line/ S

curve) Returning to reference point |

|

|

Setting coordinates Graphic simulation of machining process and real-time tracking |

|

|

Simple circular

turning Compound circular turning |

|

|

CNC programming function |

Minimum programming unit: 0.001 mm Maximum programming size: 999999.999 mm |

|

Maximum programming lines: 120000 Metric system/British system programming |

|

|

Absolute/incremental programming Macro instruction programming |

|

|

Calling subroutine Setting work piece coordinates |

|

|

Diameter/radius programming Automatic control of chamfering (round angle, right angle) |

|

|

Constant linear velocity (CLV) cutting |

|

|

Interpolation |

Line interpolation for a maximum of three axes |

|

Circular

interpolation Thread cutting |

|

|

Tool compensation function |

Tool length compensation Tool radius compensation |

|

Operation function |

8.4-inch TFT color LCD Anti-static electricity program and machine operation panel |

|

Standard PC keyboard interface Hand-held units (optional) |

|

|

Graphic display and dynamic real-time simulation Network communication (optional) |

|

|

Feed axis function |

Unrestrained axis rotation function Maximum speed: 21000 mm/min |

|

Feed speed override: 0% to 150%

Rapid movement speed override: 0% to 100% |

|

|

Various modes of returning to the reference point: single direction and

bi-direction |

|

|

Spindle function |

Spindle speed: specified by PLC programming (Maximum speed: 32000 rpm) |

|

Spindle speed override: 0% to 150% Displaying spindle speed and override |

|

|

Variation ratio and variation ratio level: specified by PLC programming |

|

|

PLC function |

Build-in PLC Standard PLC sample Displaying PLC status |

Size

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.