Features

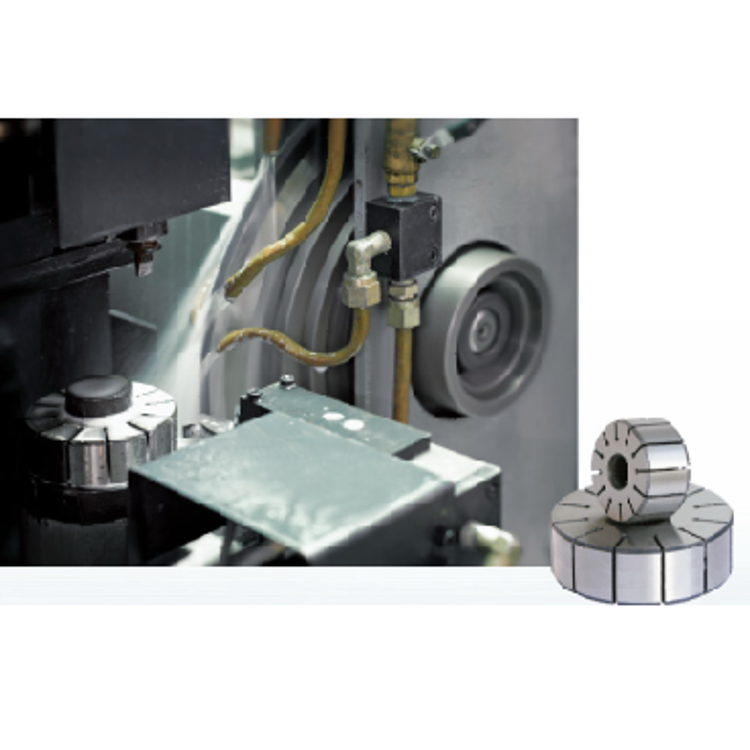

1. The RF-M1001 CNC rotor groove grinder is

used with the NC system imported from Japan and features high power servo motor

to control work radial feeding, wheel dressing auto radial compensation,

diamond roller dressing , high stiffness rolling bearing spindle system, air

sealing to ensure spindle' high precision and long life.

2. The CNC rotor groove grinder uses a CBN high speed grinding wheel and

process. The machine's main driving and feeding parameter is optimized,

attached with groove self division positioning mechanism or other positioning

mechanism.

3. It uses a huge coolant tank to guarantee grinding efficiency and accuracy.

Application

The RF-M1001 CNC rotor groove grinder is

used for grinding the high precision blade groove of vane pumps, automobile

direction booster pumps and automobile temperature controller compressor

rotors, etc.

Technical Specifications

|

Item |

Parameters |

|

|

Processing

accuracy |

Squareness |

0.008mm |

|

Parallelism |

0.008mm |

|

|

Roughness |

Ra<0.2μ m |

|

|

Main parameter |

Rotor OD |

Ф30-120mm |

|

Rotor groove

width |

1.4-5mm |

|

|

Rotor groove

axial thickness |

8-40mm |

|

|

Work groove

radial max grinding depth |

20mm |

|

|

Wheel diameter |

400mm |

|

|

Grinding

surface speed |

48m/s |

|

|

Single groove

grinding time |

0.3-1.5min

(single stock removal <0.2mm) |

|

Aluminum slit strips: a precision slitting line with minimal burring enables tension-free custom cutting for coil widths up to 2,100 mm

As a leading CNC system supplier in China, WEIHONG is now take a big step to expanding the overseas market.