MK2120 CNC Internal grinding machine

MK2120 CNC Internal grinding machine

Main characteristics of this machine tools

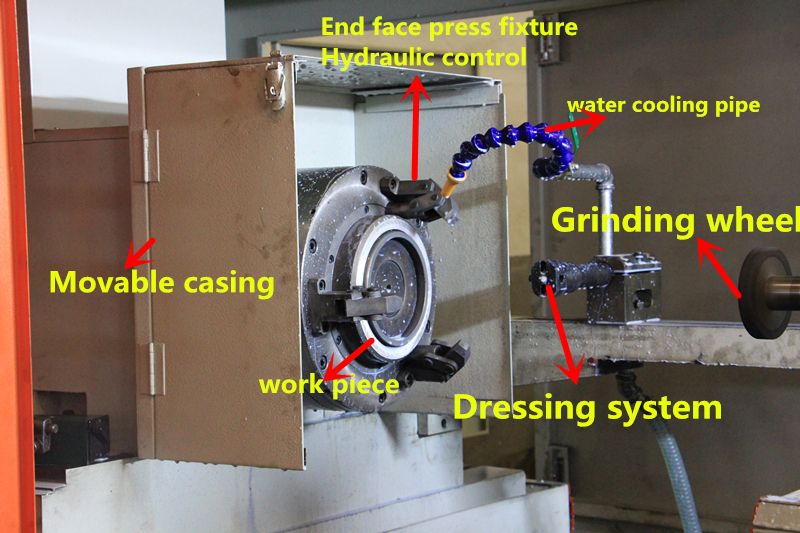

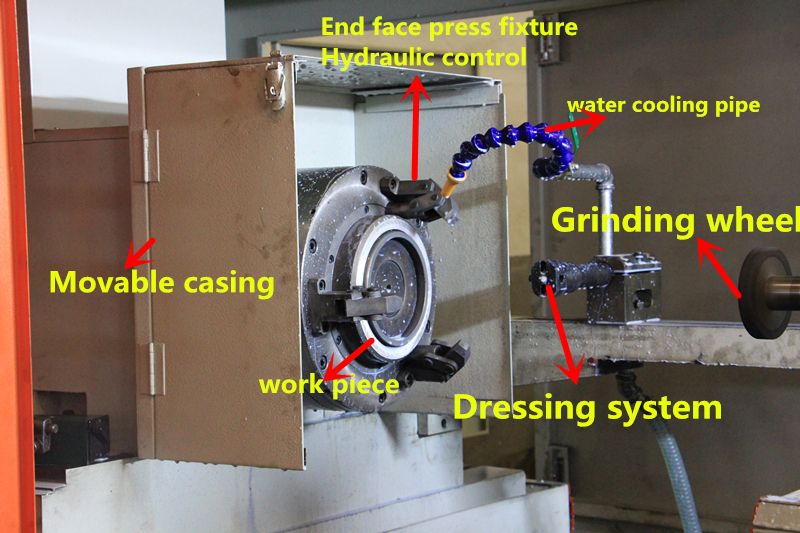

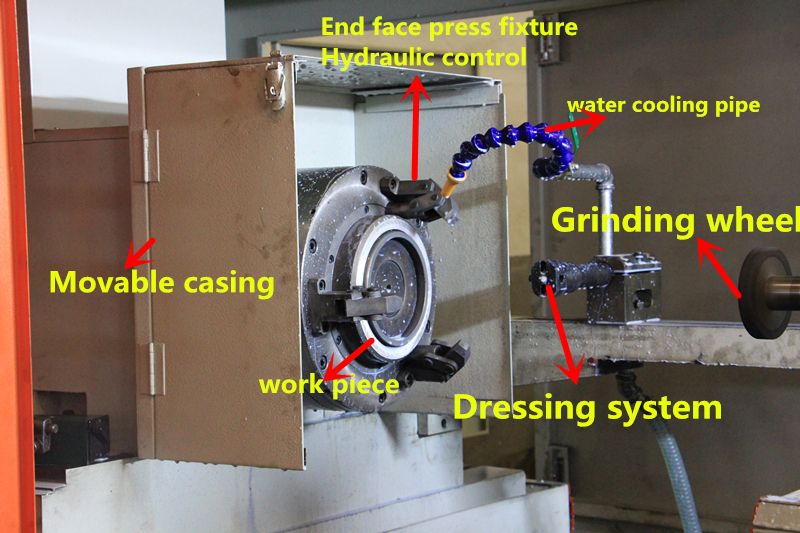

This machine tools is mainly used for grinding of internal hole, internal end face, external end face and stepped hole of work piece.

This machine tools body adopts castings with good rigidity and small deformation.

Setting and adjustment of machine tools parameters adopt touch screen. Human-machine dialogue can be realized.

All the movable guide rails of machine tools adopts high-precision linear rolling guide rails which have good sliding performance. Screws for feed and reciprocating motion adopt high-precision ball screws.

The feed system of machine tools adopt Japanese Mitsubishi servo system for double-axis linkage control.

Grinding wheel spindle of machine tools adopts high-speed motorized spindle and is controlled by static frequency converter, so as to realize stepless adjustment.

The headstock adopts high-precision ball bearing. The rotating speed of work piece is controlled by AC frequency converter to realize stepless speed adjustment.

The machine tools can be equipped with fixtures such as three-jaw chuck,hydraulic chuck,diaphragm chuck, pneumatic chuck, etc. For user to select.

The machine tools adopts fully-closed shell with beautiful and elegant appearance.

Specification parameter list

Model of machine tools | MK2120 |

Grinding diameter scope | Φ10-200mm |

Maximum grinding depth | 300mm |

Swing diameter of work piece | Inside the shell | Φ400mm |

Outside the shell | Φ600mm |

Maximum rotation angle of headstock(°) | 30° |

Rotating speed of work piece | 30-600rpm stepless speed regulation |

Rotating speed of grinding wheel | 0-24000rpm stepless speed regulation |

Power of X axis servo motor | 2kw |

Resolution of X axis | 0.001kw |

Maximum stroke of X axis | 200mm |

Power of Z axis servo motor | 3kw |

Resolution of Z axis | 0.001mm |

Maximum stroke of Z axis | 600mm |

Power of work piece motor | 2.2kw |

Power of grinding wheel motor | 7-15kw |

Total power of machine tools | 23.8kw |

Outline dimension of machine tools | 3100x2120x2000mm |

Weight of machine tools | 4500kg |

Working accuracy(according to standard specimen | Roundness of internal hole | 0.002mm |

Cylindricity of internal hole | 0.003mm |

Surface roughness of internal hole | Ra0.4um |